Use Cases

We work hand-in-hand with CERN equipment owners to develop state-of-the-art designs based on their specifications, agreeing with the Groups, who maintain the final responsibility of the equipment, the main design choices.

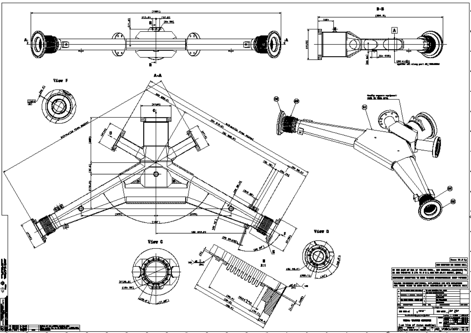

Vacuum chambers for ELENA

Overview

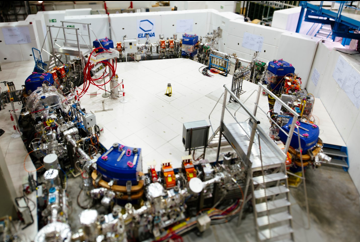

ELENA is the new CERN Extra Low Energy Antiproton ring (ELENA) with the task to further slow antiprotons from the Antiproton Decelerator, to make them easier to trap.

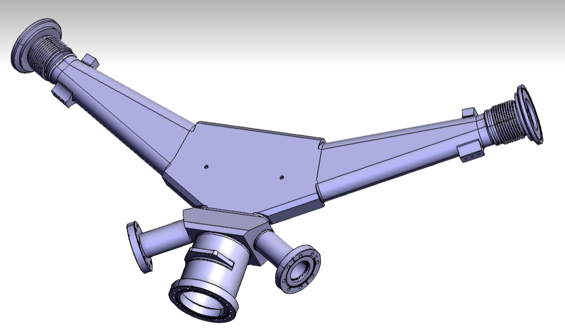

Our Design Office designed the full set of ELENA vacuum chambers !

A 30 m circumference synchrotron which take antiprotons extracted at 5.3 MeV from the Antiproton Decelerator (AD) and further decelerate them down to 100 keV has been built at CERN. From the vacuum point of view, machine requirements imposed a very low average pressure at 4.0E-12 mbar.

Challenge

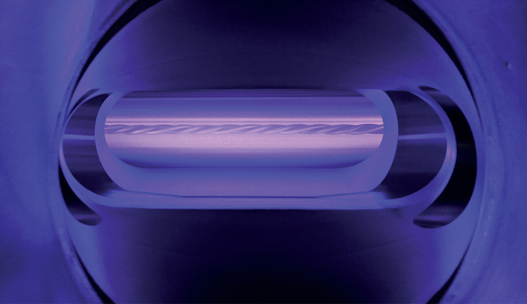

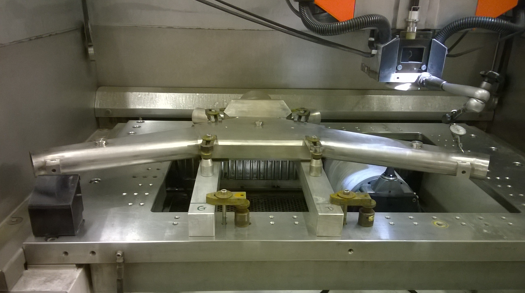

Vacuum requirements demand state-of-the-art solutions to reduce the potentially large outgassing of many components installed inside the vacuum system: to fulfil the stringent internal pressure level, vacuum chambers shall be fitted with NEG-coating, vacuum firing, bake-out ribbon heaters and integrated NEG-ion pumps.

Solutions

Close interaction with the workshop allowed our Design Unit to provide the full set of 3D models and manufacturing drawing for the vacuum chambers of the ELENA decelerator. Complex chambers, such as the dipole chamber represented in the above pictures, required as well contribution of our Engineering unit to assess the final design against the applied mechanical and thermal loads.

Reference: https://cds.cern.ch/record/2141876/files/wepha010.pdf

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Design Office can do for you.