Use Cases

We work hand-in-hand with CERN equipment owners to develop state-of-the-art designs based on their specifications, agreeing with the Groups, who maintain the final responsibility of the equipment, the main design choices.

Mechanical design of a new end cap structure for CMS

Overview:

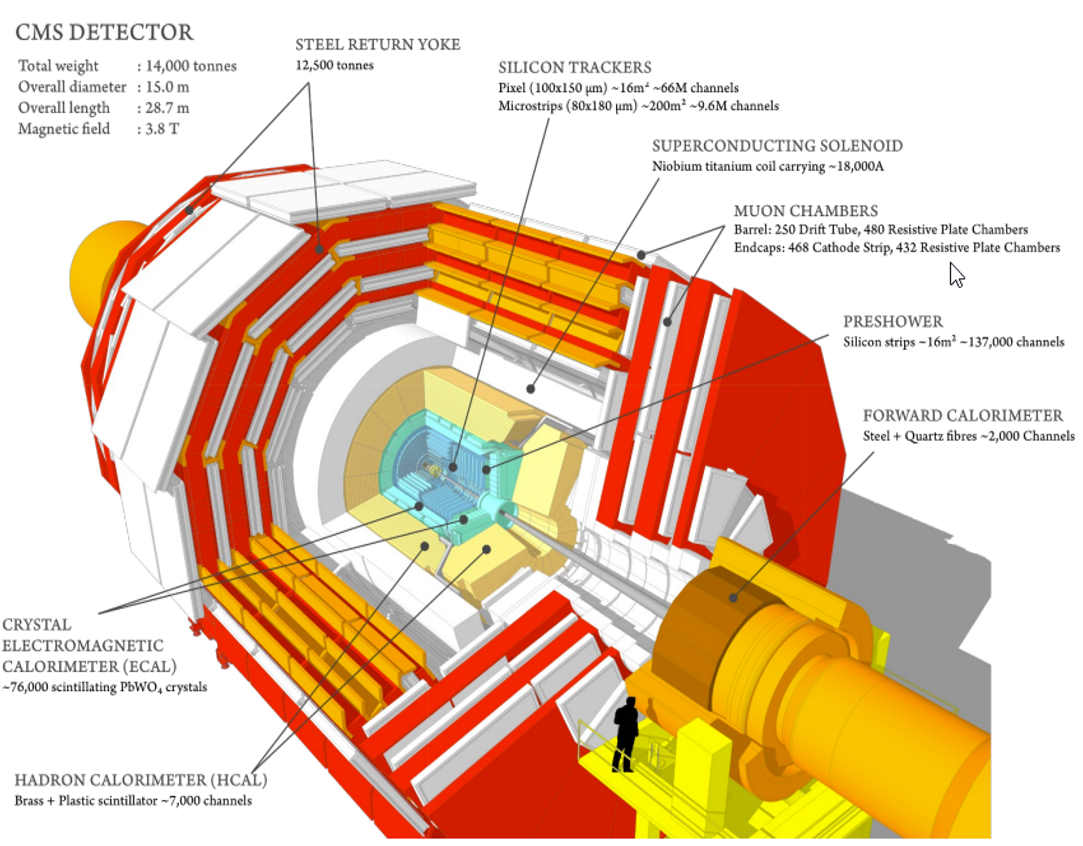

As part of the CMS end cap High-Granularity Calorimeter(HGCAL) upgrade for the Long Shutdown (LS3) a new structure needs to be designed and built to host the new detector components offering enhanced resolution, timing, radiation tolerance when exposed to the new High-Luminosity Large Hadron Collider (HL-LHC) conditions.

Challenge:

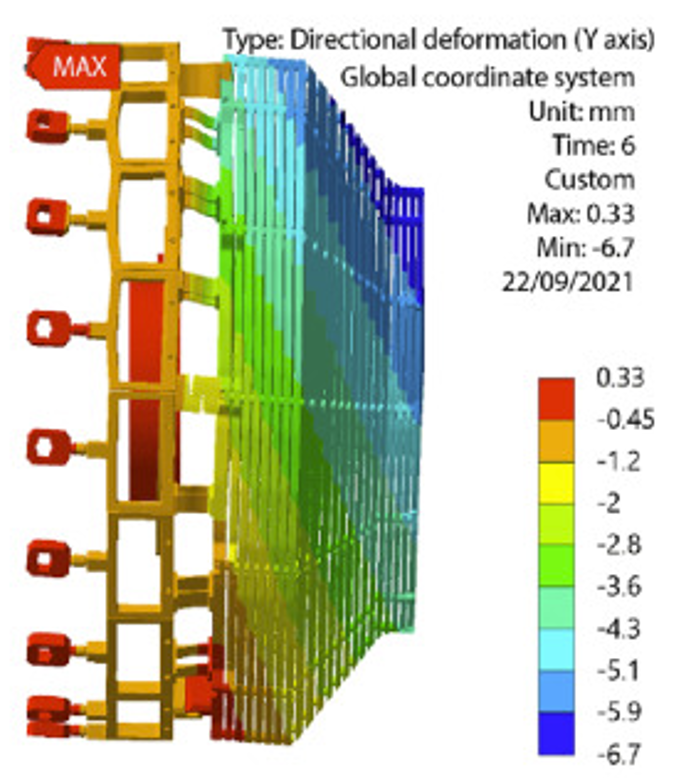

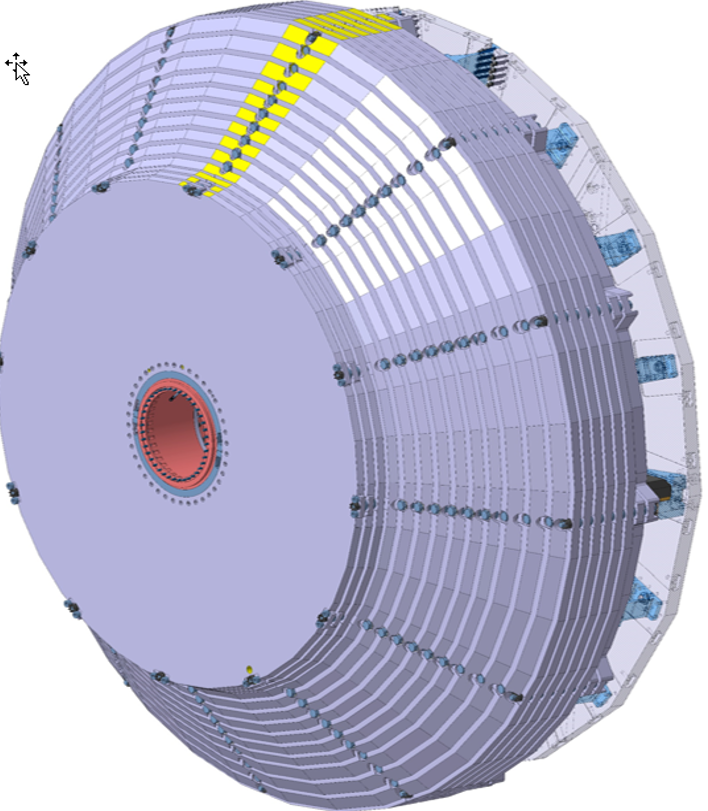

The HL-LHC endcap must integrate delicate detector elements within tight envelopes while supporting ~220 t of self-weight and resisting strong electromagnetic forces. Large stainless-steel plates (5 m diameter, 60 mm thick) must maintain flatness below 1mm with total deformations of its 21 piled-up plates kept below 10 mm. Achieving this precision requires robust mechanical design and anticipation of the full chain from machining and metrology to assembly, transport, and underground installation

Solutions:

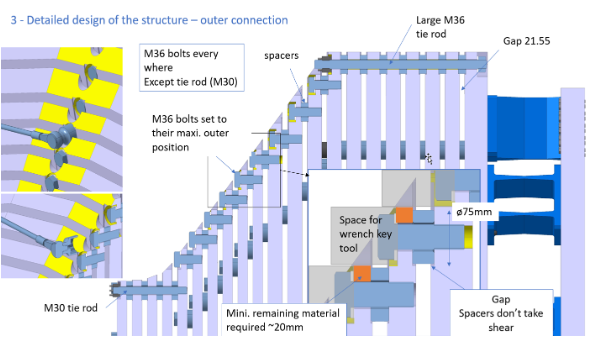

The cylindrical tapered endcap (Ø 2.5–5 m) is built from 21 plates made from stainless steel with low permeability, each split into three bolted sub-parts for transport and assembly. High-strength bolts (up to 600 MPa) combined with precision dowel pins provide slip-critical, preloaded joints with controlled shear transfer and repeatable alignment. Precision machining, strict QA, and laser tracker surveys ensure a common flatness plane across all seams. The structure withstands ~220 t self-weight and electromagnetic forces while keeping global deformation below 10 mm, guaranteeing stable long-term performance under HL-LHC conditions.

BENEFITS

- Facilitates transport and handling by dividing the endcap into manageable sub-parts.

- High-strength bolts and dowel pins ensure rigid, reliable joints that withstand ~220 t self-weight and electromagnetic forces.

- Flatness tolerances are controlled through a design-to-manufacturing approach and verified by laser tracker metrology, keeping deformations below 1 mm over 5 m and ensuring proper insertion of the detector components.

- Features for assembly tooling are embedded inside the design.

- Strict material procurement specifications contain permeability values to reduce electromagnetic forces on the structure.

OUTCOME

This solution delivers a robust, precisely aligned endcap that protects detector components, ensures stable performance under HL-LHC conditions, and minimizes risks and downtime, strengthening CERN’s ability to achieve world-leading physics results.

FIND OUT MORE

Keen to learn more about our activities?

Find out what the Design Office can do for you.